Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

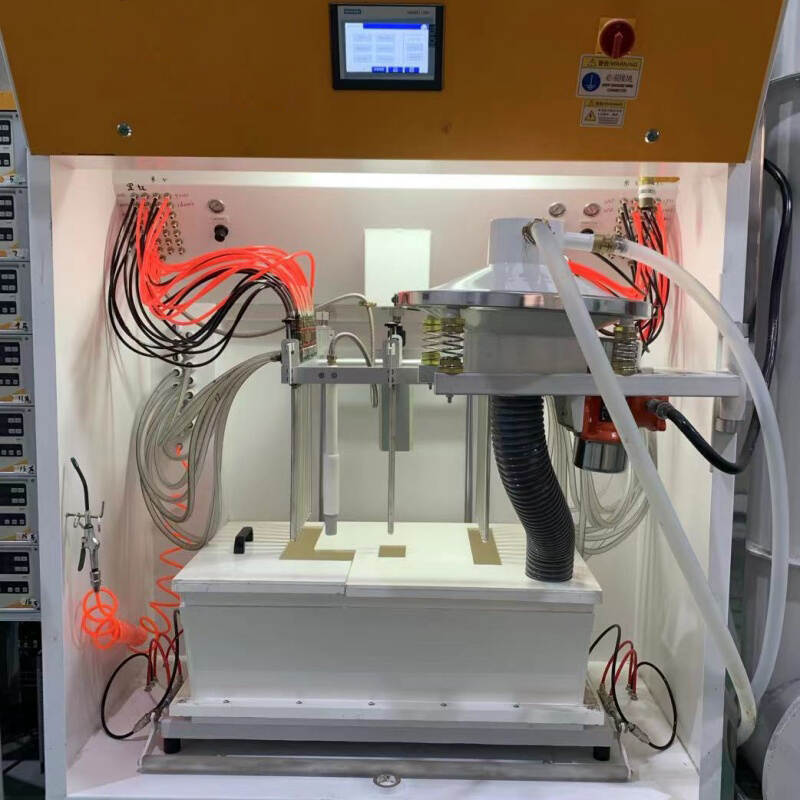

Explosion-proof Large Cyclone Automatic Powder Recovery Spray Booth

The Explosion-proof Large Cyclone Automatic Powder Recovery Spray Booth is an advanced powder coating system engineered for efficient powder separation, high recovery rates, and enhanced surface coating quality. Designed to meet the needs of high-volume industrial users, this booth is ideal for manufacturers looking to reduce powder waste, improve coating consistency, and streamline operations with a high-performance recovery system.

At its core is a large cyclone separator, optimized to capture up to 95% of powder overspray, allowing for fast, continuous reuse of powder materials. This system is also explosion-proof and meets strict safety requirements for powder environments.

Key Features & Benefits

High-Efficiency Cyclone Separation Technology

The large cyclone separator utilizes centrifugal separation, capturing usable powder and separating ultra-fine particles with outstanding efficiency. Up to 95% recovery rate, reducing material waste and improving environmental compliance. Ensures clean air discharge and superior air-powder separation.

Automatic Powder Recycle & Screening System

Powder collected at the base of the cyclone is fed to a vibrating sieve, where impurities are filtered out. Clean, reusable powder is returned to the supply bucket, ensuring smooth, uninterrupted spraying. Built-in powder pump ensures reliable powder transport.

Explosion-proof & Durable Construction

Constructed using high-strength iron plates and reinforced section steel for long-term durability. Equipped with explosion-proof components to meet safety regulations for volatile powder environments. Quick clamp connections enable rapid assembly, disassembly, and maintenance.

Technical Specifications

|

Component |

Specification |

|

Recovery Efficiency |

Up to 95% |

|

Separation Method |

Centrifugal cyclone air-powder separation |

|

Material – Cone Wall Plate |

Iron plate, thickness δ = 3 mm |

|

Material – Cyclone Barrel |

Iron plate, thickness δ = 2 mm |

|

Material – Top Fan Casing |

Iron plate, thickness δ = 3 mm |

|

Material – Powder Hopper |

Iron plate, thickness δ = 3 mm |

|

Structural Frame |

High-strength section steel |

|

Powder Transfer |

Powder pump with vibratory sieve |

|

Explosion-Proof Rating |

Compliant with industrial explosion-proof standards |

|

Surface Treatment |

Phosphating for inner/outer pipe surfaces |

Working Principle

The cyclone separator operates based on centrifugal force. As powder-laden air enters the cyclone chamber, it rotates downward along the cyclone wall. In the conical section, rotation speed increases, generating strong centrifugal forces that drive heavier powder particles outward toward the wall. These particles lose momentum and drop into the powder hopper below, while the cleaned air reverses direction, spiraling upward and exiting through the exhaust duct.

Collected powder is transported to a vibrating sieve, where contaminants are removed before the clean powder is reintroduced into the spray process — ensuring consistent powder flow, optimal surface coating quality, and reduced waste.

Advantages

- Significant Powder Savings through high-efficiency recovery

- Improved Coating Quality with screened, reusable powder

- Explosion-proof Safety Design for industrial powder environments

- Low Maintenance Costs thanks to durable construction and accessible cleaning ports

- Compact, Integrated Design that fits seamlessly into automated powder coating lines

- Environmentally Friendly by minimizing waste and airborne dust

Application Areas

- Aluminum Profiles and Ceilings

- Automotive Frames and Parts

- Furniture Hardware Components

- Electrical Cabinets and Enclosures

- Heavy Machinery and Industrial Equipment

Perfect for OEM powder coating manufacturers, industrial metal coating plants, and high-throughput finishing facilities seeking better powder efficiency and surface results.